Our last RoboTar arrived in Germany... We had a little trouble getting through customs and getting the package in Martin's hands. Martin is our first regular Mac user. We had a bump during install which was quickly addressed by Mirek (our star lead developer) with an updated install.

Martin has been patient and very helpful as we continue to refine and improve RoboTar. We learned our lesson that UPS or FedEx might be a better way to go for International deliveries over the USPS. Shipping is more expensive but I think duties will be better addressed through those companies but we will see.

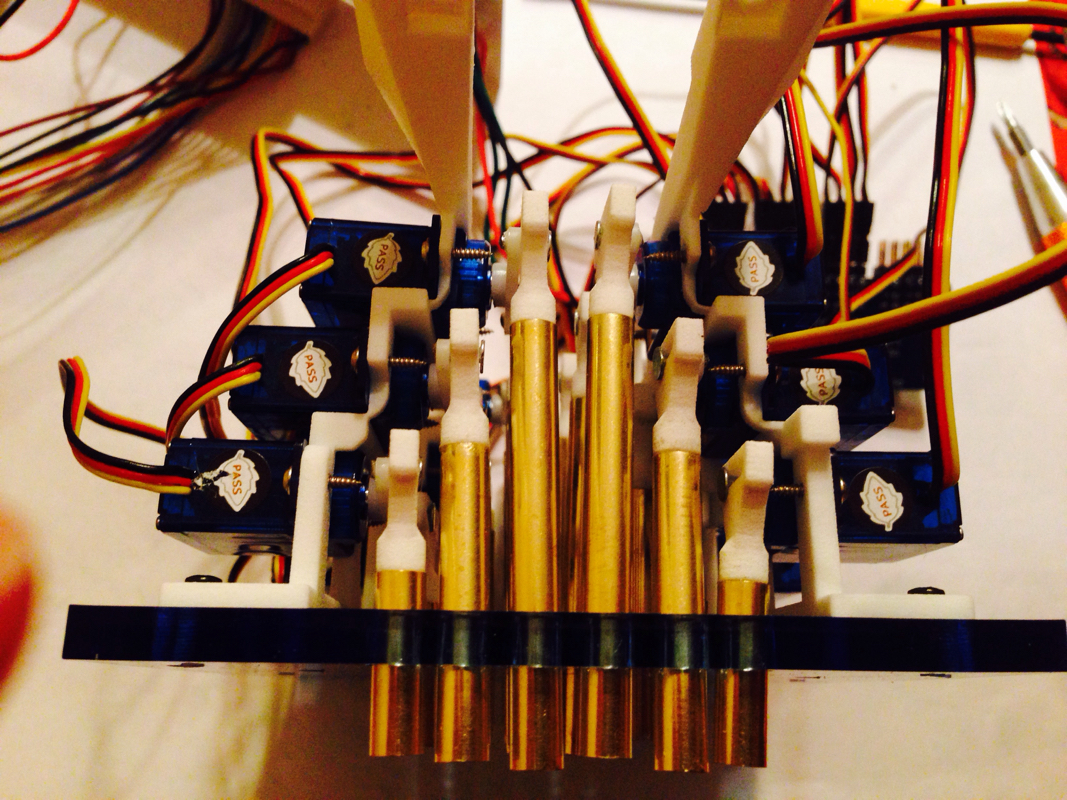

Next up is Slava in Israel. Attached is a Video of Slava's RoboTar. I just received the and installed the 3d printed finger pads. They were a little big for the brass fingers required some special fitting adjustments but we should be able to get Slava his RoboTar by mid January.

The manual build process is slow but is becoming more repeatable. It is a great way to refine the product and continuously improve but I must admit it is difficult for me and for customers who would like to have their RoboTar in their hands sooner rather than later. I appreciate everyone's patience and I look forward to the day when we have enough RoboTar's to warrant a manufacturing strategy. Complex hardware projects like RoboTar are hard to fund. We have a specialized market but I know once the word begins spreading there will be many other interested parties. Can't sell without product, but can't manufacture a product without sales... We'll figure this out... others have.

Martin has been patient and very helpful as we continue to refine and improve RoboTar. We learned our lesson that UPS or FedEx might be a better way to go for International deliveries over the USPS. Shipping is more expensive but I think duties will be better addressed through those companies but we will see.

Next up is Slava in Israel. Attached is a Video of Slava's RoboTar. I just received the and installed the 3d printed finger pads. They were a little big for the brass fingers required some special fitting adjustments but we should be able to get Slava his RoboTar by mid January.

The manual build process is slow but is becoming more repeatable. It is a great way to refine the product and continuously improve but I must admit it is difficult for me and for customers who would like to have their RoboTar in their hands sooner rather than later. I appreciate everyone's patience and I look forward to the day when we have enough RoboTar's to warrant a manufacturing strategy. Complex hardware projects like RoboTar are hard to fund. We have a specialized market but I know once the word begins spreading there will be many other interested parties. Can't sell without product, but can't manufacture a product without sales... We'll figure this out... others have.

RSS Feed

RSS Feed